Prefab 101

Why a home built in a factory might be a key to solving our underinsurance problem

This guide was built in partnership with CityLAB, LA4LA and ARRC. It was fact-checked by licensed professionals and building experts. Consult a builder or architect for specifics to your situation.Prefabs are misunderstood

Like any new development in an industry that’s been around a long time, there is a lot of resistance to change. From “they’re trailers” to “you can’t change anything about them”, misinformation about prefab houses abounds.

We think they’re a pretty great solution to the octopus of issues fire survivors are navigating, so we partnered with the team behind the Altadena Prefab showcase to make sure myths don’t get in the way of what might be a great option for you.

Here’s a rundown of the basics.

Myth:

“Prefabs are trailers.”

This is a common confusion between “Manufactured Homes” and pre-fabricated houses.

“Prefab” simply refers to the way that a home is built; Ie, in a factory, before it gets to your lot.

Fact: “Prefab” houses* are built to the same building codes as ones built on site.

*Manufactured Homes are classified differently.

what’s a

“Manufactured”

Home?

Often called “mobile homes,” “single-wide,” “double-wide”, think of these more like a car. They are typically thought of as personal property (not real estate), and they usually depreciate with time.

Manufactured homes are built on a steel chassis, so they can be moved - unless you permanently install it on a foundation and convert it to a single-family residence, you can’t get a regular mortgage on a manufactured home.

Things to know:

Manufactured homes typically have different insurance coverage, higher mortgage interest rates, and can’t be expanded or adjusted in the same way site-built or pre-fab houses can.

Unless specifically built to high fire-resiliency standards a manufactured home can be a tricky choice for someone living in Altadena or the Palisades. In areas that have suffered through mega-fires, getting insurance can be difficult and expensive unless your home is built to certain resiliency levels so if you’re considering a manufactured home, explore ones that are built to IBHS Wildfire Prepared Standard.

Because manufactured homes are built to HUD standards, retrofitting to meet IBHS Wildfire Prepared Plus Standard can be quite difficult.

You can read more on the importance of building to IBHS standard to being able to afford your new home insurance premium here.

Can I build

a regular house

prefab?

Yes!

You can build a traditional house in a factory. Prefab houses can be customized, built to the highest level of resiliency & energy efficiency, and are indistinguishable from site-built homes.

Once installed on a permanent foundation, prefab houses:

Appraise like site-built homes

Qualify for standard mortgages

Appreciate in value over time, just like a regular home

The only difference between a prefab house and one built on site is that it’s built in advance.

Myth:

“Pre-fabs are pre-designed”

Fact: You can build almost anything you can build traditionally in a prefab factory. There are a number of prefab manufacturers near LA that can build custom architectural plans.

“Prefab” doesn’t dictate the style, quality, or layout.

Most prefab options today:

Offer plan catalogs you can choose from, and/or

Work with you and your architect to adapt your custom design to their system

Can handle a wide range of styles and layouts, with some limitations for what can be shipped and craned

Some details (porches, decks, special rooflines, custom elements) might still be built on site, but most homes you see on the street could now be built in a prefab factory.

what do “Modular” and “Panelized” mean?

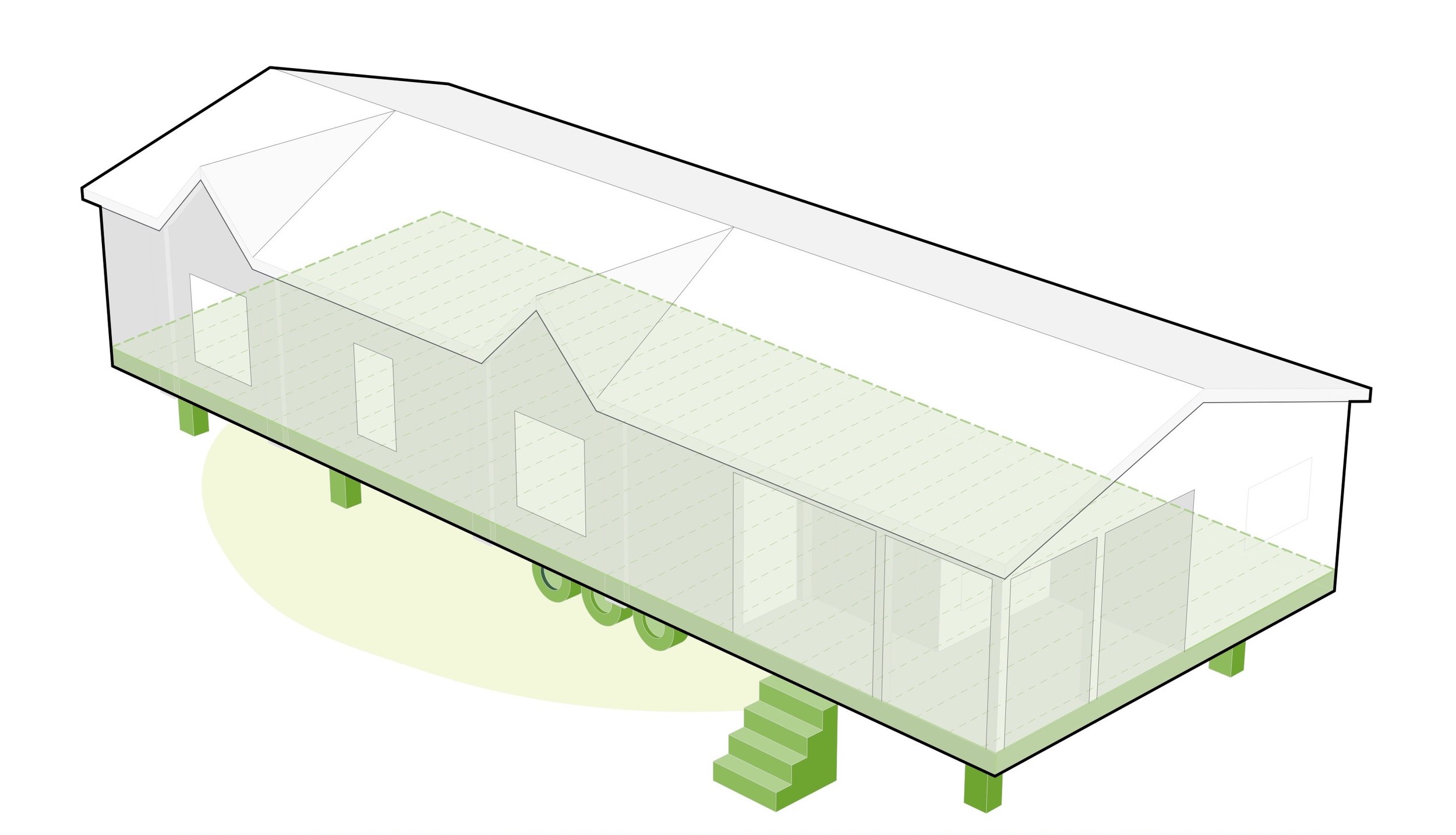

Pre-fabricated houses are constructed and delivered in two ways, each completely customizable depending on the factory you go with.

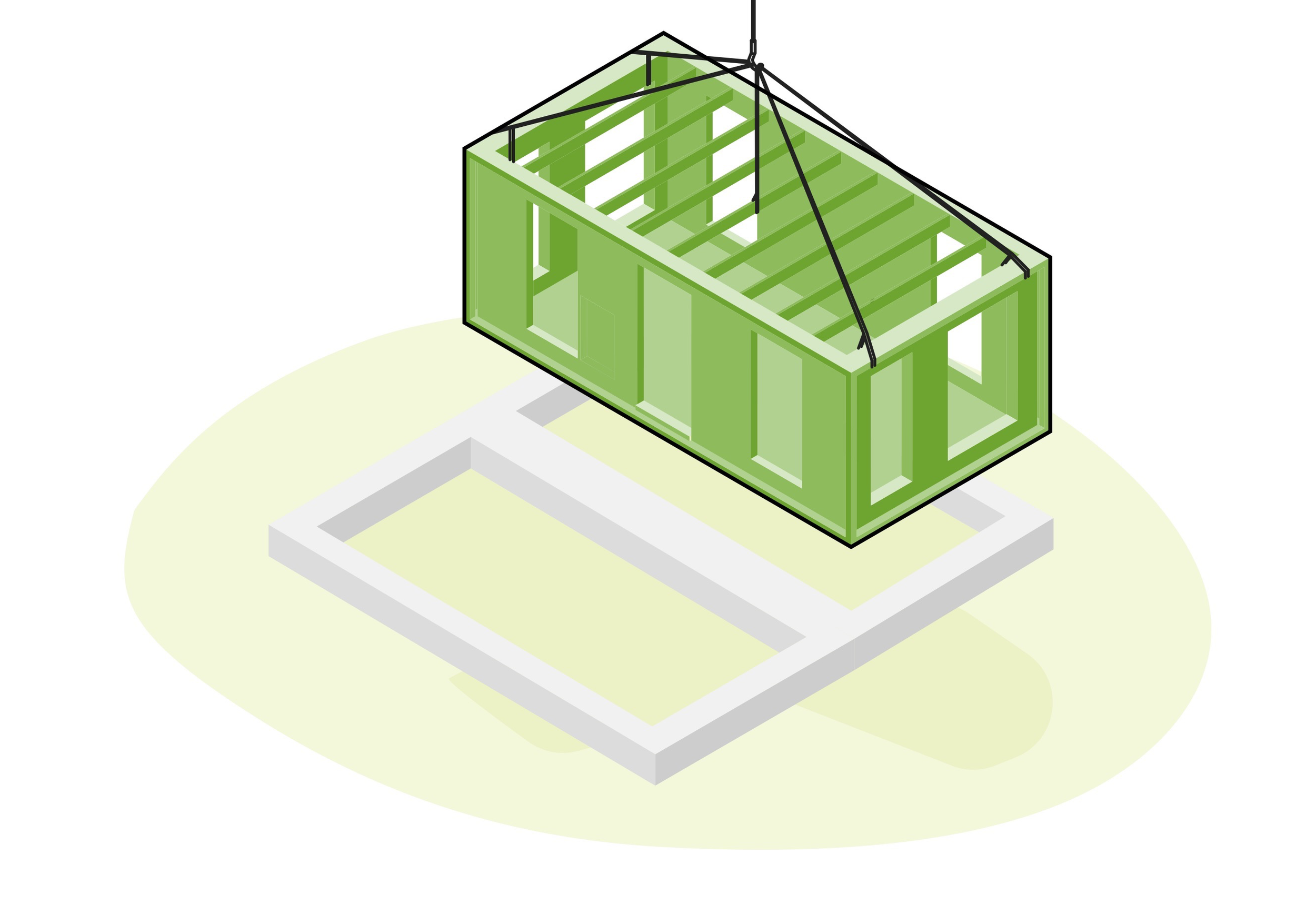

“Modular” means entire rooms are constructed and delivered in cubes, which are then attached to the foundation and to each other.

Modules can be fully finished with plumbing, electrical, drywall, paint, etc, and dropped on your property ready to go, or they can be delivered open and finished on site.

Some modular manufacturers operate as GC, so your full process is handled by the same company; others require you to hire your own GC for your foundation, assembly of the mods, and utility connections.

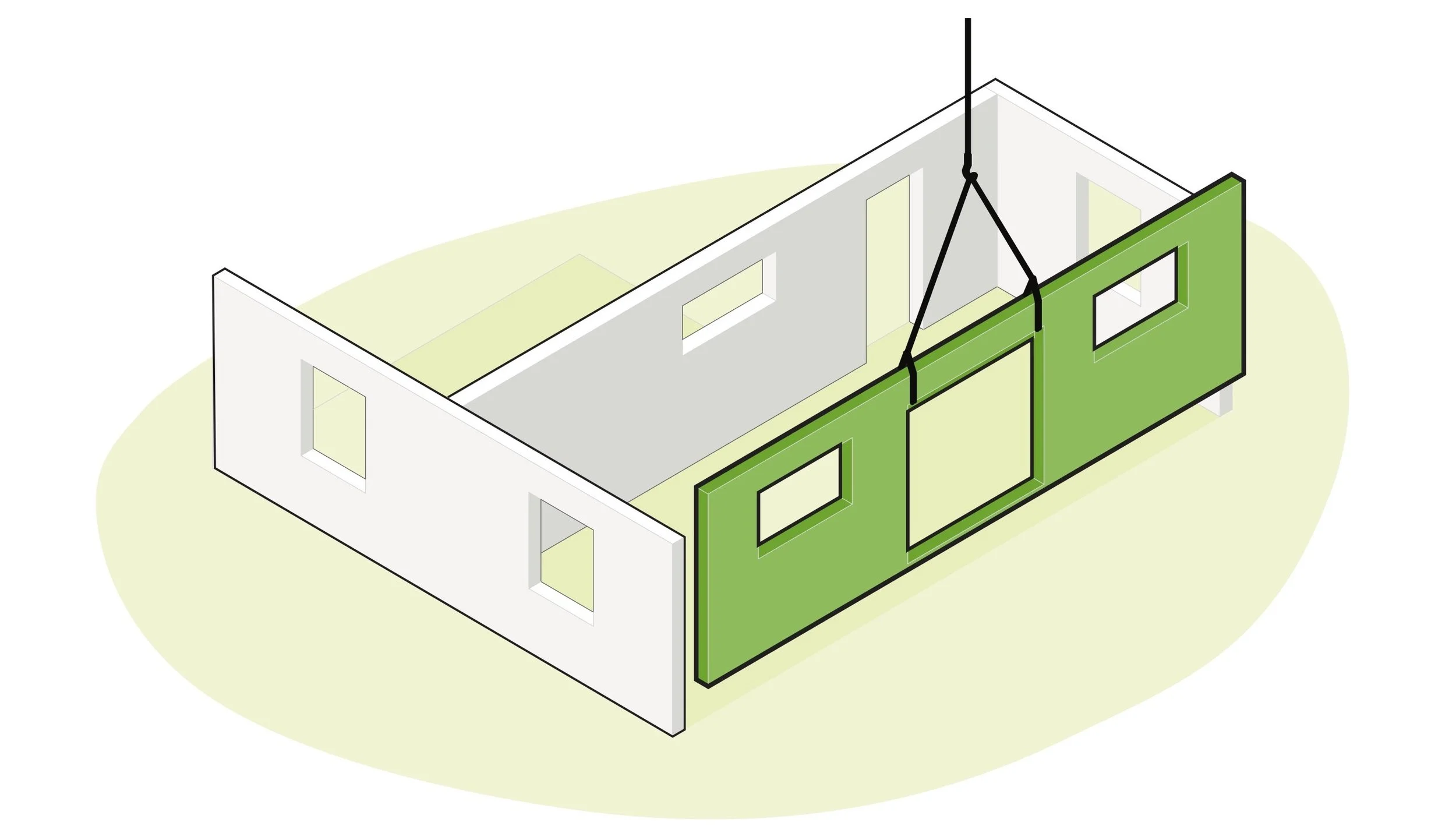

“Panelized” means the house is built in panels (think pre-built walls), delivered flat-packed, and then assembled and finished on site.

Panels tend to need a lot more work once they reach the job site because they require more assembly and finish work.

Some panelized manufacturers operate as General Contractors so your full process is handled by the same company; others require you to hire your own GC for your foundation, assembly of the mods, and utility connections.

“Why are pre-fabs

so great for

fire survivors?”

-

Site-built custom homes often take 18–30 months.

A well-managed prefab build can land closer to 6–15 months.

While your lot is being prepped (demo, grading, foundations), your home is being built at the same time in the factory.

No waiting on weather, disappearing subs, or materials sitting out in the rain.

With limited housing coverage, this can lift a huge burden.

-

Modern prefab companies can design around:

IBHS Wildfire Prepared / Wildfire Prepared Plus strategies

Chapter 7A/WUI requirements

Fire-resistant siding and roofing

Enclosed eaves, ember-resistant vents, covered gutters

Tight, well-insulated, energy-efficient envelopes

Because it’s built indoors with precision, it’s often easier to hit energy codes, comfort goals, and wildfire standards, which will be essential for us if we want to stay off the FAIR plan.

-

Factory construction (partially done by high precision machines) reduces:

Mistakes or on-site improvisation

Inconsistent workmanship between subs

The waste, costs, and headaches associated with all of those things

With limited budgets and the complexities of navigating insurance and mortgage escrows, this would make for one less stressor.

-

With most of the value being built indoors, there’s:

Less risk of rain delays

Less material damage

Less risk of theft off your lot

Less personality clashes

Some folks may be able to absorb complications and delays, but most of us just want to get home as quickly and easily as possible.

Myth:

“It’s not cheaper

than a regular build”

Fact: While it is true that prefab construction is not inherently cheaper than site-built homes, it’s the other stuff that tips the scale:

The cost (financially and emotionally) of being displaced

Surprises and errors that can cost thousands

The exhausting toll of 12+ months of decisions and potential personality clashes

FAQs

-

When a prefab home in California:

Meets California Residential Code, and

Is installed on a permanent foundation,

it’s treated like any other stick-built house for:

Appraisal – appraisers use comparable (site-built) homes, not manufactured homes.

Financing – you can use construction-to-permanent loans, regular mortgages, SBA loans, and certain FHA disaster programs.

When selling - There is no difference in the sale process with a pre-fab home.

Many lenders actually like prefab because the controlled process can reduce risk and cost overruns.

-

Yep, insurers treat prefabs exactly the same as stick-built homes. Their primary interest will be the level of resiliency it’s built to, and what your finishes are.

-

Yes! Your Coverage A/B/C/D proceeds should be able to fund a modular or panelized rebuild just like a traditional build.

Is PreFab a

Fit for You?

Prefab is worth a serious look if you:

Want a faster, more predictable path home

Are dealing with underinsurance and need fewer unpleasant surprises

Have a site that’s reasonably accessible for deliveries (or can use panelized/hybrid systems)

Why isn’t

everybody

doing this?

A lot of people are! It may not be the norm partially because of misinformation, but also because pre-fabs aren’t perfect. Here are some of the downsides:

-

Some prefab companies act as your GC.

Others only build the panels/modules and you still need a local GC to handle foundations, site work, assembly, and utility connections.

Either way, someone has to manage the site side of the project.

-

For some lots (tight canyons, steep roads, dead-ends, tricky access):

It may be hard or impossible to bring in large trucks and cranes.

Fully modular may not work, but panelized or hybrid systems still might.

-

Because pieces need to be shipped and lifted:

Some shapes, spans, and rooflines aren’t possible with certain manufacturers

Hyper-custom, one-off architecture may not be a good fit.

If you want something wildly unusual, prefab might not be your path.

-

Factories often require:

Larger upfront deposits

Progress payments before the home leaves the factory

Site work to be fully ready before your delivery window

If your site isn’t ready when your house is, you can lose your slot or face storage/holding costs.

Some options

Plant Prefab

Bakersfield, CA

Modular and Panelized builds

Can do full custom architecture

Eco-friendly factory

BevyHouse

San Diego, CA

Modular and Panelized builds

Can do full custom architecture

Can act as your GC as well, creating a turnkey experience

B.Public

New Mexico

Modular and Panelized builds

Can do full custom architecture

Specializes in Passive Homes